Why Some Woods are Better than Others in the Kitchen

8th Dec 2023

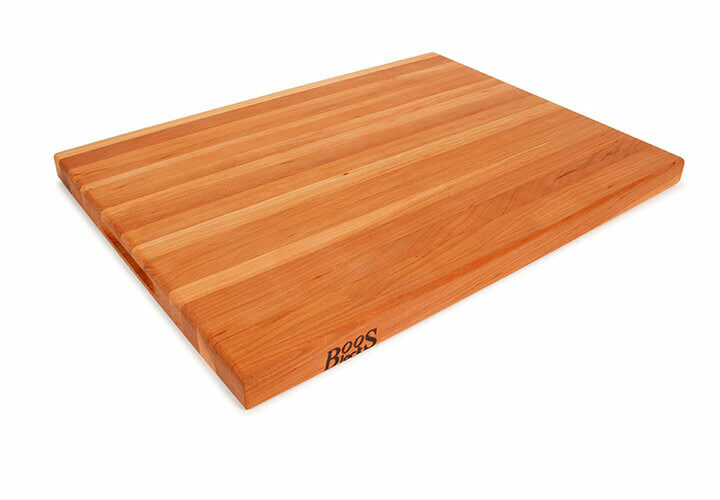

When it comes to choosing the perfect cutting board, the type of wood you select can make a significant difference in both performance and longevity. While there's a wide variety of wood species available, not all woods are created equal in terms of suitability for cutting boards. In this article, we'll delve into the reasons why some woods are better for cutting boards than others. Here are our best selling woods that we would recommend for any kitchen. Read on for some of their best features.

Our Best Selling Woods

|

|

|

|

Maple |

Walnut |

Cherry |

|

|

|

|

Teak |

Bamboo |

Larch |

Hardness

One of the most crucial factors to consider when selecting wood for a cutting board is its hardness. Hardwoods, which come from deciduous trees, are generally preferred due to their durability and resistance to knife marks and deep cuts. They have hard, tight grains that increase durability and longevity. There are a variety of beautiful grains to choose from - light, dark, rich and even boards with a mix of all of the above. They also require only occasional, easy maintenance. We recommend John Boos Mystery Oil.

Traditional Hardwood Recommendations: Maple, Walnut, and Cherry

Contemporary Hardwood Recommendations: Teak, Acacia, and Olive.

Softwoods

Sometimes, it may be beneficial to use a softwood board. They are the most gentle on knives and will prolong their sharpness. There are also some delicate and high-quality knives that might be more prone to chipping or dulling on harder surfaces, such as some Japanese knives that are hand crafted and not as easily replaceable. These are also some of the best woods for kneading dough or rolling out pastry.

Manufacturers such as Larch Wood, make blocks from softwoods, but solely use end-grain construction to retain durability. End grain puts the wood fibers at the surface of the board, so that knives run against the end of the fibers, instead of across. This design prevents the fibers from splitting and scarring.

The aesthetic appeal of more exotic looking softwoods do create a striking presence in the kitchen. Depending on the kitchen style, these can be very complementary. Finally, softwoods are generally much lighter than hardwoods, which can make them easier to carry or move around in a busy kitchen.

Softwood Recommendations: Hinoki and Larch Wood.

Antimicrobial Properties

Antimicrobial cutting boards are designed to help prevent the growth of bacteria on their surface. This can be beneficial for a number of reasons.

Bacteria can cause foodborne illness, and cutting boards that are not properly cleaned can be a breeding ground for these harmful microorganisms. Antimicrobial cutting boards can help to reduce the risk of foodborne illness by killing bacteria on their surface. Antimicrobial cutting boards can help to improve food safety by making it less likely that bacteria will be transferred from raw meat, poultry, or fish to other foods. This is important because bacteria can easily spread from one food to another, and cross-contamination can lead to foodborne illness.

Antimicrobial cutting boards can help to extend their lifespan by preventing bacteria from damaging the wood. This is important because cutting boards that are damaged can harbor bacteria more easily. These woods are often easier to clean than other cutting boards. This is because the antimicrobial properties of the wood help to kill bacteria on the surface, making it less likely that bacteria will be able to grow and multiply.

Antimicrobial Recommendations: Maple, Olive, Teak and Hinoki.

Why Some Woods Don't Work

Oak is a hardwood, but is not often used in cutting boards. The reason is that oak, while hard, has very large pores. When these pores are cut through they are visible to the naked eye. Large pores cause the same problem as cuts and scratches – they harbor bacteria and can cause water-logging. Woods like hard rock maple, walnut, cherry (all materials used by John Boos), and teak are considered “close grain,” meaning they have small pores for a smoother surface less friendly to bacteria.

Wood toxicity is a concern for woodworkers who are exposed to the raw materials and wood dust. Wood toxicity can take the form of irritation, sensitization, and even poisoning. While a typical cutting board user isn't exposed to wood dust, it does raise the question of whether wood is food safe. Oils and resin can leach into foods you are preparing, so it is important to consider in the case of rare or exotic woods not typically used in cutting board construction.

Rosewood is a good example. It is a rich, dark brown timber prized for its beauty and hardness. However, some people are sensitive to the oils it leaches. While there are very few woods that are viewed as toxic after being finished, it is important to remember that some individuals are more sensitive than others.

Environmental Concerns

There are many complicated issues surrounding the use of lumber such as questions about habitat destruction, deforestation, sustainability, and human and economic rights. Some of the most durable and beautiful wood for cutting boards, guitars, and furniture are also endangered. The Convention on International Trade of Endangered Species (CITES) was an agreement formed between governments in 1973 that established protection for species including trees. There is also the International Union for the Conservation of Nature (IUCN) which identifies, maintains, and publishes a “red list” of tree species that are in danger. You are probably familiar with their classifications: critically endangered, endangered, and vulnerable. Certain types of mahogany, walnut, ebony, and teak can be found on these lists.

All cutting boards and butcher blocks sold on CuttingBoard.com are certified sustainable or renewable, but other vendors are not as careful about their sourcing. It is important when considering a cutting board to think about the environmental ramifications, especially if it is made from a type of wood that you are unfamiliar with. Ask questions and chop responsibly.